Dryer Section Passivation

Maintech offers industry leading solutions for the issues caused by troublesome deposits on dryer cylinders, dryer fabrics, and rolls.

As the inventor and pioneer of Dryer Section Surface Passivation, Maintech's accumulated experience and knowledge are unrivalled in the paper industry.

Maintech's dryer section passivation experience is based on over 1000 reference applications on over 300 paper machines worldwide.

Dryer Cylinder Surface Passivation

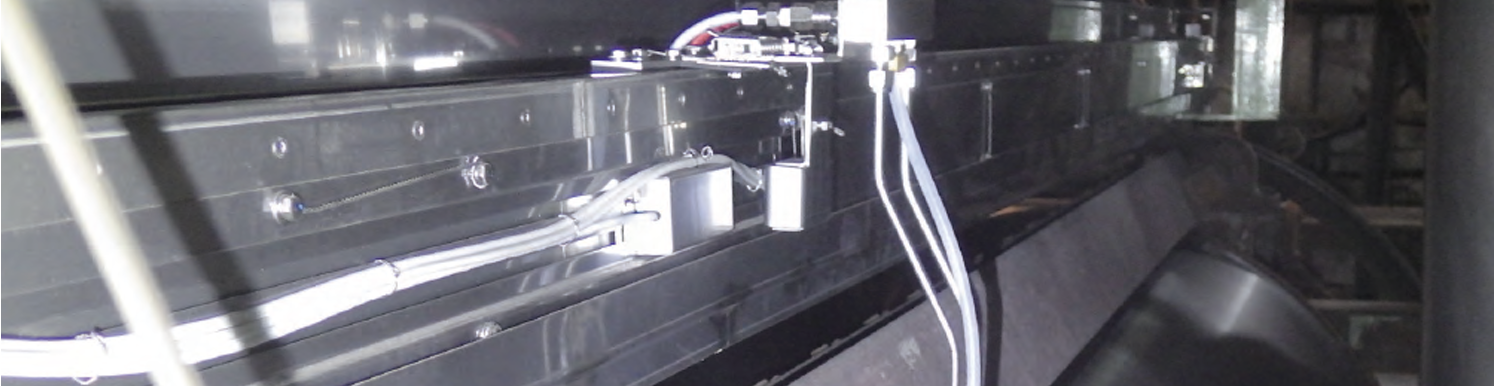

Maintech's Dryer Cylinder Surface Passivation System combines their highly effective release chemical (DusClean), robust and reliable traversing spray hardware (MistRunner), and extensive application knowhow to reduce stickies, deposits, and linting on the dryer cylinder surface.

Dryer Fabric Surface Passivation

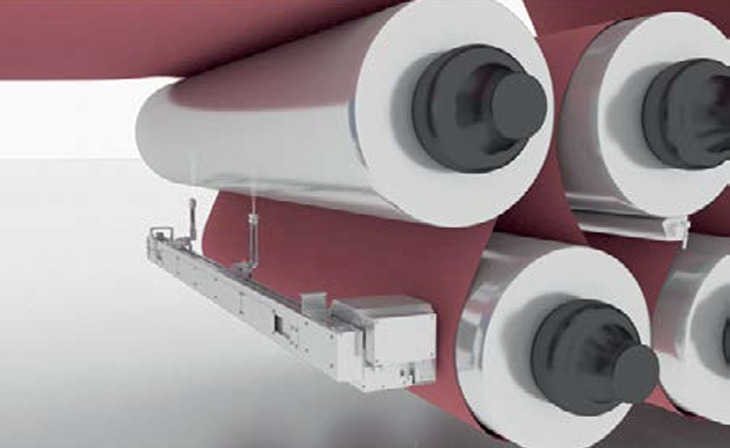

Maintech's Dryer Fabric Surface Passivation System combines their specially formulated release chemical (CleanKeeper), robust and reliable traversing spray hardware (ShowerRunner), and extensive application knowhow to reduce stickies and linting on the dryer fabric surface.

Key Benefits

- Reduced dryer section sheet breaks

- Improved runnability in the dryer section

- Increased drying capacity, enabling increased production

- Extended dryer fabric life

- Reduced operator's manual cleaning with aggressive chemicals

- Reduced steam consumption and pressure

- Improved paper quality, including defect reduction, paper smoothness, and moisture profile

Maintech Europe GmbH

Theodorstrasse 297

40472 Düsseldorf

Germany

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.