Specialists for Stock, Additive, and Starch Preparation

PGA has been part of the IBS Paper Performance Group since 2014.

PGA provide innovative systems and components for fibre treatment, the preparation of additives, mass and surface starch as well as coating kitchens.

Products and Solutions

Audit for Starch Plants

The addition of mass and/or surface starch in the papermaking process is an essential factor in producing the highest paper qualities. Thanks to PGA's knowhow and experience, they can carry out a condition assessment for starch plants - regardless of the manufacturer. Based on the assessment, PGA suggest possible optimisation measures to reduce starch consumption and leverage further cost-saving potentials.

PGA starchPERFORMER

The starch cooker PGA starchPERFORMER revolutionises the preparation of mass and surface starch.

Benefits:

- Highest flexibility in the use of different starch varieties.

- Fast changeover between starch types.

- Maximisation of quality and efficiency of surface starch.

- Reduced starch and steam consumption.

- ROI possible in less than 1 year.

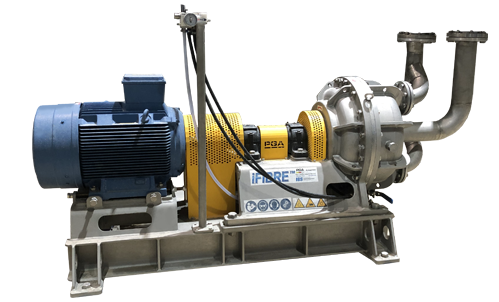

iFIBRE deSAVER

The deSAVER is especially designed to improve the efficiency of existing screening plants in waste paper-based stock preparations. Its area of application is in the reject line of stage 1 or 2 in the fine screening mostly. Alternative areas of application are in the coarse screening or fractionation. The deSAVER significantly reduces reject quantities and thus fibre losses.

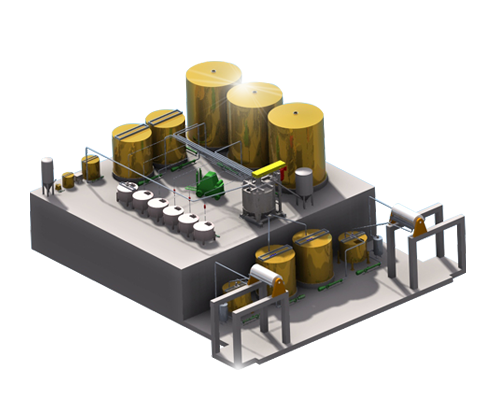

Mass and Surface Starch Preparation

Complete plants and rebuild solutions for all types of starch.

PGA's starch plants are suitable for all types of starch and are designed for product uniformity and ultimate reproducibility. They supply complete plants as well as modular retrofitting solutions.

Coating Kitchens

PGA have been in the pigmenting and coating colour preparation business for over 20 years. They support their customers with process expertise and supply standard and customised solutions for the paper industry. As well as new systems, PGA also offer customised rebuilds and optimisation solutions to help their customers meet market demands.

Disperger Plants

PGA are a flexible and customer-orientated partner for the filler and dispersing plant business and offer the following processes.

- Unloading system for silos and Big Bags

- Silo and Big Bag stations

- Powder dosing

- PGM disperser systems (developed by PGA)

- Slurry storage

- Slurry dosing

- Filter systems

- Automation and control systems

- Auxiliary systems (tanks, steel works, piping, fittings, …)

PGA Anlagenbau GmbH

Gewerbeweg 3

9241 Wernberg

Austria

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.